Design for Manufacturing

Purpose: To design parts, assemblies so they’re easy, cost-effective, and reliable to manufacture.

Minimize Part Count

- Tooling Setups , Fasteners, Assembly Time, Lower Inventory

Standardize Materials and Manufacturing Process

- Off the shelf materials + Select on: How strong? Thermal properties, how heat resistant? What colour? Insulator or Conductor?

- Standardized Manufacturing process for your part volume

- Low Volume: 3D printing, CNC Machining, Machine Shop

- High Volume: Injection, Die Casting, CNC, Sheet Metal, Extrusion, Stamping, Forging, Casting

Tolerance Parts Appropriately

- Only specify tight tolerances when required, depends on application (0.01mm)

- High Tolerance: CNC spindle shaft application: Rotates cutting tool, critical surface where shaft slides on roller bearings.

- Weak tolerances = runout = vibration.

- High RPM with small radial runout = high force on bearings

- Part being machined is inaccurate. Radial runout = wobble of turn, Axial runout = up and down motion

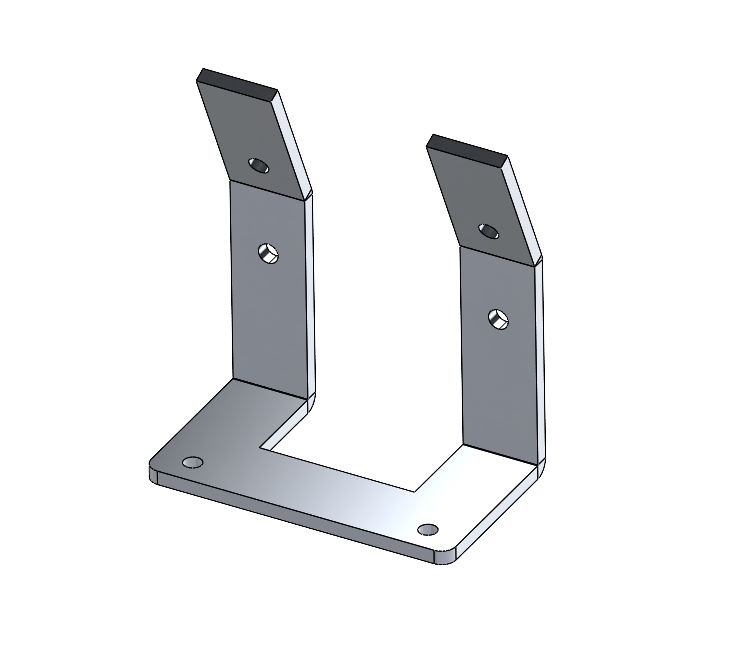

- Low Tolerance: Sheet Metal bracket to fasten a control panel.

- Holes and bend angle can have low tolerances because hole misalignment will not cause issues with clearance holes

Why Does Tolerancing Affect Cost?

- Requires more expensive equipment

- Slower spindle speeds to avoid deflection and vibration = more time

- Custom fixtures required, off the shelf vices won’t do the job

- Post processing inspection = increased time

- Reject rate increases = wasted time and material

- Requires specialized machinists

Self-Locating Features

- Such as bosses, tabs and chamfers that guide assembly and fixturing

Design for Process Selected

- Align holes, reuse fixturing points, and use symmetrical features

Capstone

Base Plate: Standard steel material 201 annealed steel

- Available for easy purchasing

- Great machinability due to its reduced hardness (cleaner holes, less chatter marks or burns)

- Cheapest option

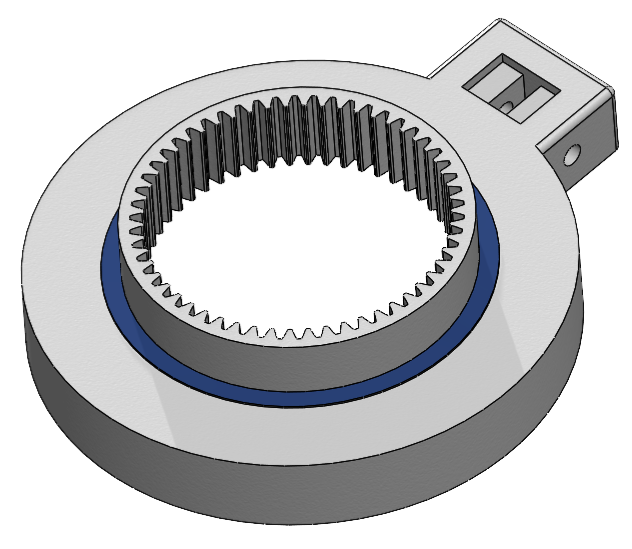

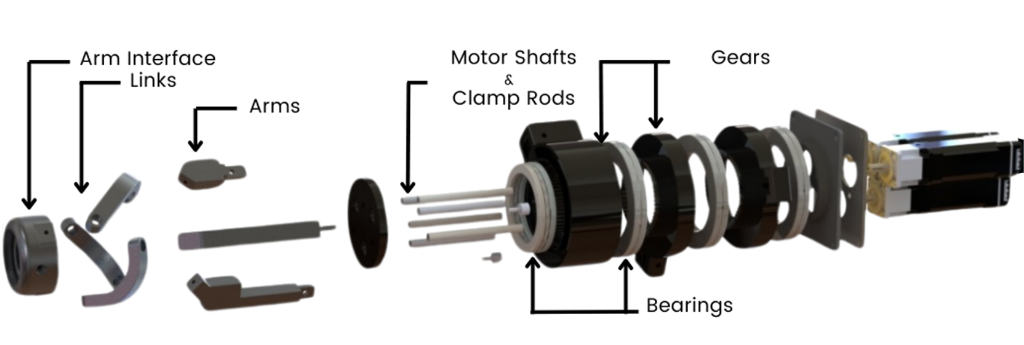

Pinion and Gears

- No available gears to purchase – CNC or 3D print

- 3D printing option was selected due to budget limitations

- Selected carbon fiber nylon for its strength to weight ratio, and it is the strongest material available at the print shop

- Our module of 1.5mm was large enough for good 3D printing quality after printing small prototypes

Arm and Links

- Used off the shelf available material 6061 aluminum and made the design as simple as possible

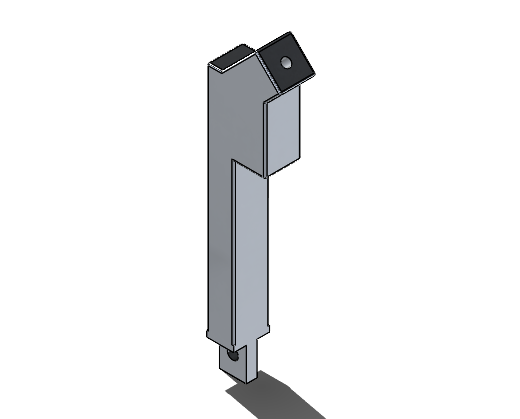

End-Effector

- Made one solid part to reduce the quantity of parts and eliminated any additional fasteners

- Designed for CNC machine as internal holes were lined up with the external holes to make them accessible

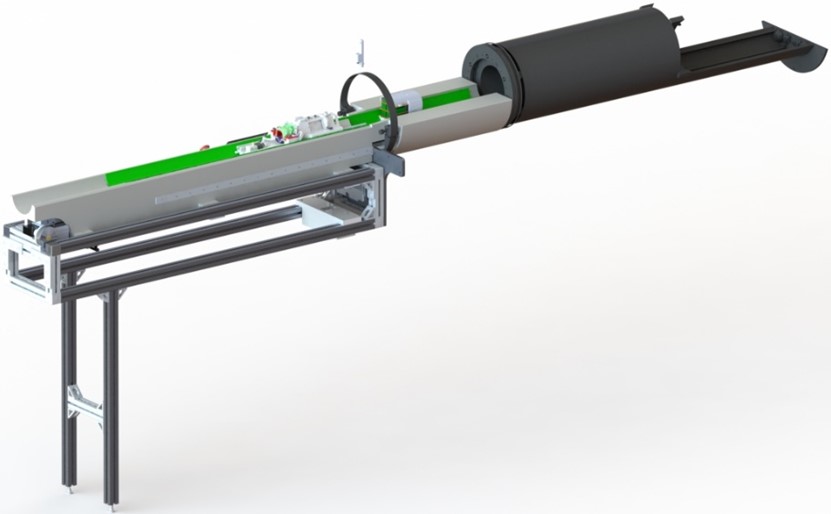

MRI Bed

- Designed all parts to be manufactured in house via bandsaws, 3 axis CNC machine, Drill press, and hand tools

- 3D printed parts designed, or spliced for build volume restrictions

UW Robot

- Chassis and parts are 3D printed

- Designed parts in accordance with manufacturer’s guidelines -> Build Size (780x780x530), Wall thickness (0.8mm), Embossed and Engraved details, and Tolerances 0.3mm

Design for Assembly

Purpose: To design parts, assemblies so they’re easy and time-efficient to manufacture.

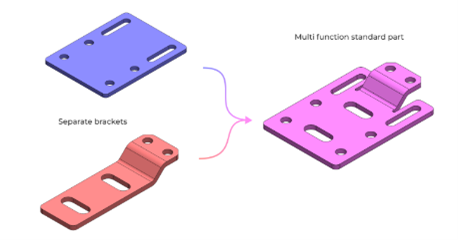

Minimize Part Count

- Aim to use multi-functional components

- For each component, ask yourself “is this part necessary at all?

- Can a part’s primary function be performed by another part already in the assembly

Reduce Fastener Types & Counts

- Favor snap fits over screws. If screws are appropriate, limit sizes used.

Self‑Locating & Self‑Fastening Features

- Incorporate chamfers and lead‑ins so parts naturally align and latch without external fixtures.

Design for Handling

- Ensure parts are big enough and shaped for easy pick up by hand or robot gripper; avoid tiny, delicate pieces that require tweezers.

Minimize Assembly Operations

- Strive to eliminate non value added steps: no reorientation, no secondary tooling changes, no adhesives or curing steps unless essential

- Top-Down Assembly, use gravity

Symmetry & Orientation Control

- Wherever possible, use symmetrical parts or keyed features so components can’t be installed backwards.

Capstone Project:

- Easy Stackable Design. Uses an orientation with gravity to easily assemble.

- Standardized the same M6 screws for all arms and links.

- Hole to identify location of long link, as it is a fraction of a millimeter different.

- No adhesive curing steps

- PVC tube arm screws accessible after installation.

MRI BED:

- Designed for assembly and disassembly (installation) to the scanner.

- All fasteners outside the scanner, designed as an attached one unit piece, so easy slide out.

Filter Prototype:

- Minimized all fasteners.

- Modular, and Stackable design, easy assembly.

- All filters have symmetry so there is no incorrect orientation available for stackable design.