MRI Bed Project

Problem Definition

- To design and build a motorized MRI bed for a MRI scanner, for marmoset monkeys

- Current method of inserting the monkeys into the scanner was a manual push in technique, where the technician would use a push stick to guide the tray into the internal coil.

- Problem #1 of this method:

- No way to accurately place the monkey at the center of the coil, which is essential to MRI technicians to maximize the signal to noise ratio, which means that the desired area of imaging is further away from where the coil listens best .

- This correlates to crisper images and ensures that there are no shading regions which can appear like false legions.

- Previously if the technician didn’t insert it into the correct position, he would have to constantly leave the computer to make small adjustments, which is a huge annoyance, and impacts the time to scan subjects. High demand from researchers, lead to more research findings, the goal of the company.

- Problem #2:

- it induces vertigo and nausea into the monkeys. The simple explanation is that the mechanical push method causes the monkey to be pushed in too fast due to technician laziness, and that the tray gets stuck on the guide do to the lack of lubrication.

Goals:

- Precision Positioning. The designated starting point of the subject should travel to a precise distance within +/- 1mm to standardize image location. This value was provided by the MRI technician.

- Vibration Elimination: minimize vibrations transmitted to the subject to reduce image artefacts and improve scan quality as much as possible.

- Slowly introduce the animal into the scanner at 20-25mm/s to eliminate all vertigo and nausea. Provided by the veterinarian.

Roles and Responsibilities:

- All mechanical and electrical design, sourcing and procurement, and the assembly of all the parts was done by me.

- I collaborated with the machinist to get parts machined

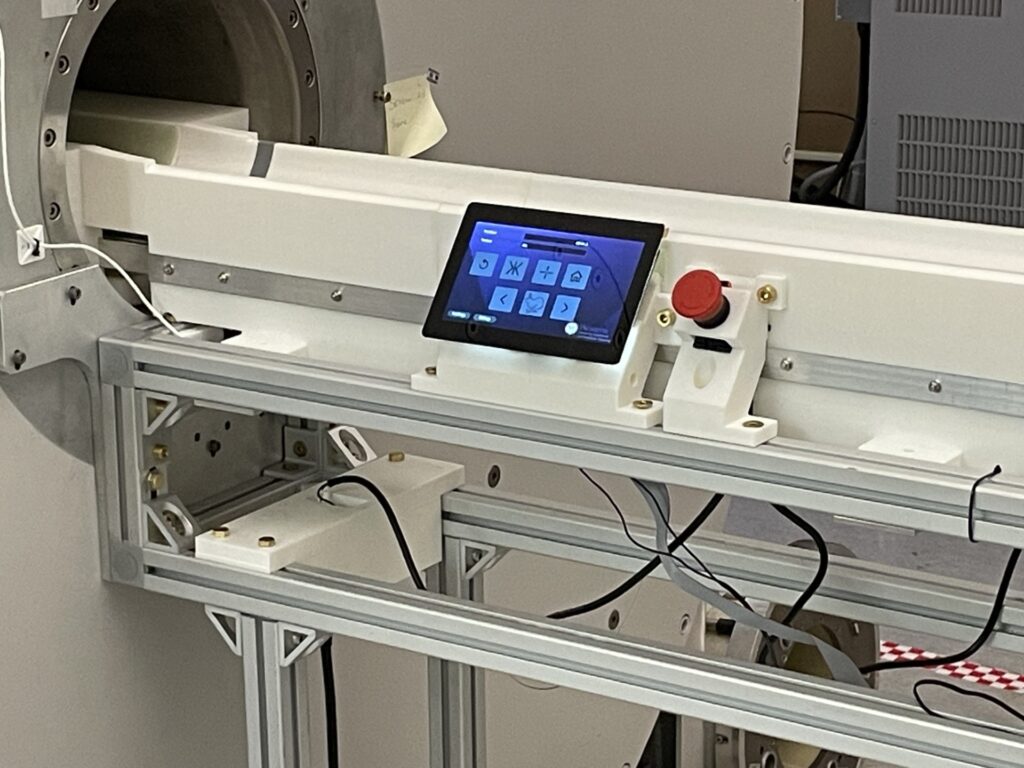

- I wrote initial firmware and designed an appealing User Interface for the touchscreen controller

Technical Approach and Design:

Step 1: Identified the main constraints of the mechanism.

- A length of 1.5m that does not impede people from walking around the MRI scanner

- Mechanism should be as simple as possible, to minimize complexity of machining, and purchasing specialized components

- Initial constraint that the bed should be on a removeable cart and easily removeable from the scanner

- Predefined tray length and size that the marmoset lats on. 1.6m in length.

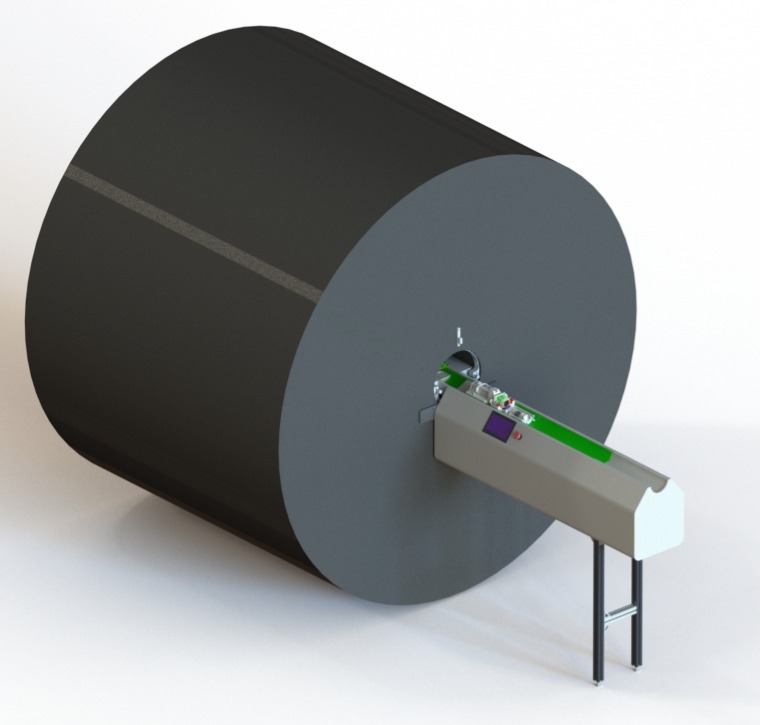

- Predefined coil diameter, and distance to isocenter. (950mm)

- Every part must be non-magnetic. Plastic, aluminum, brass, 316 stainless steel allowed outside the bore.

Step 2: Conceptually decide what the general mechanism was going to be. I sketched out multiple concepts to brainstorm ideas, from using research information to gather ideas, and look at existing MRI beds in the facility to create my own ideas.

Having the tray fully outside the bore makes the bed greater than 1.6m. 2 Options developed:

Option#1

- A complex system which will require more components. The mechanism used would be a telescoping slide rails as shown in the video here: https://www.youtube.com/watch?v=UY8QPGjWncY&t=147s&ab_channel=AutomaticGatesExplained

Option #2

- Have the tray sit partially inside the bore of the scanner, to reduce the length of the bed. The marmoset will remain outside the bore and allow the veterinarians full access before actuating the bed.

- This method was selected as it is the simplest solution that doesn’t have any drawbacks.

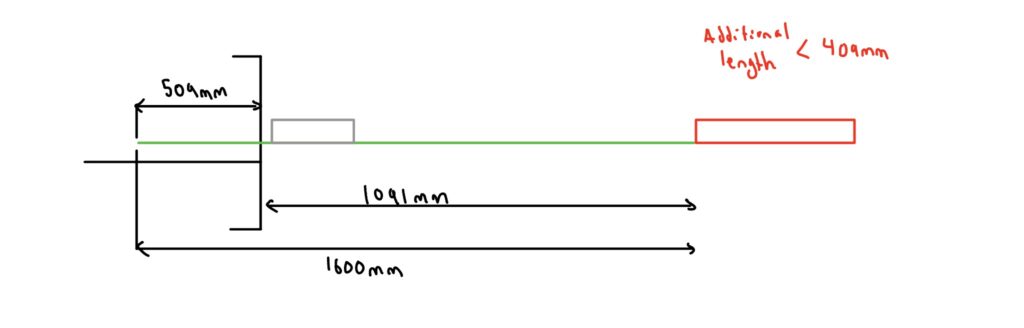

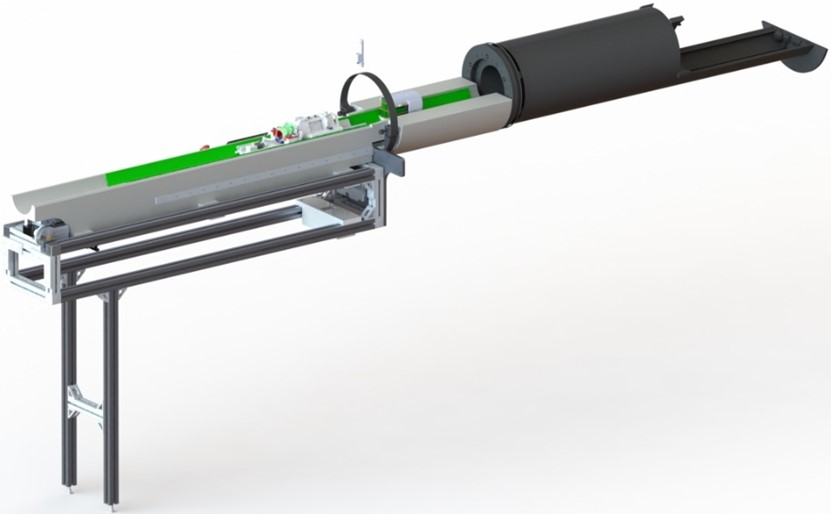

- Below is the general sketch.

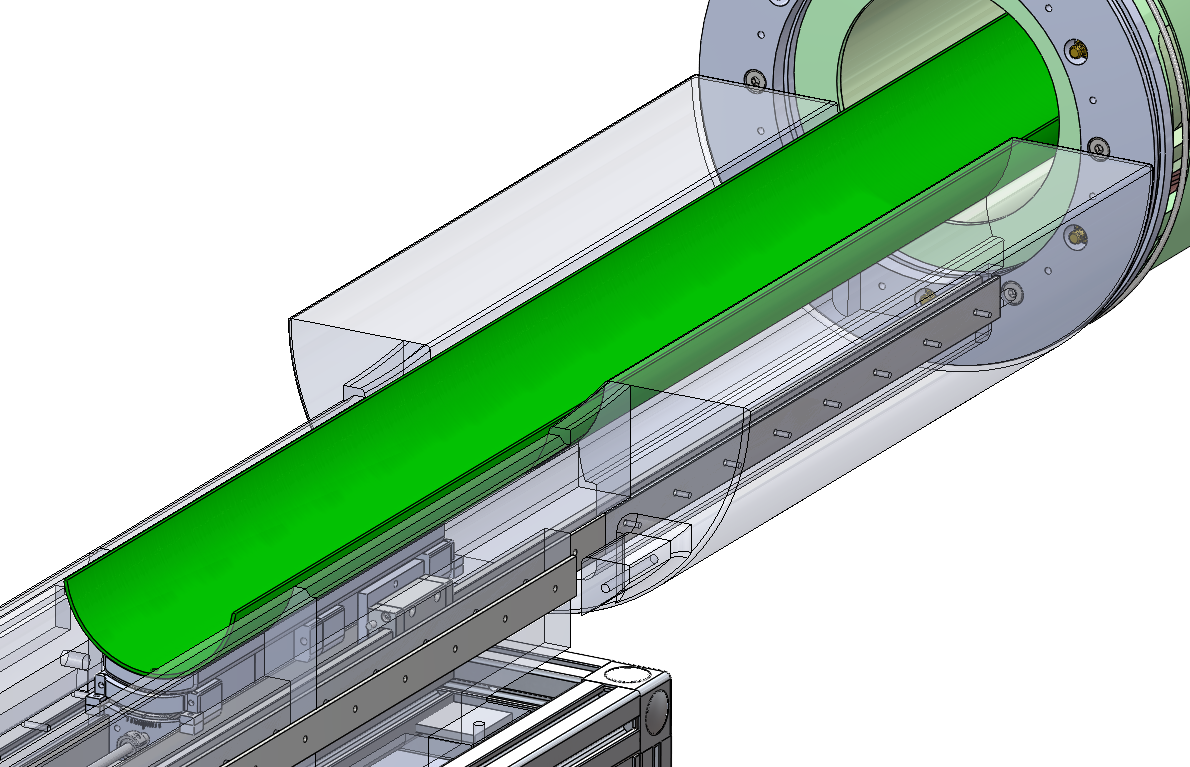

Step 3: Solve the problem of having the bed easily removeable and no mechanism inside the bore of the scanner.

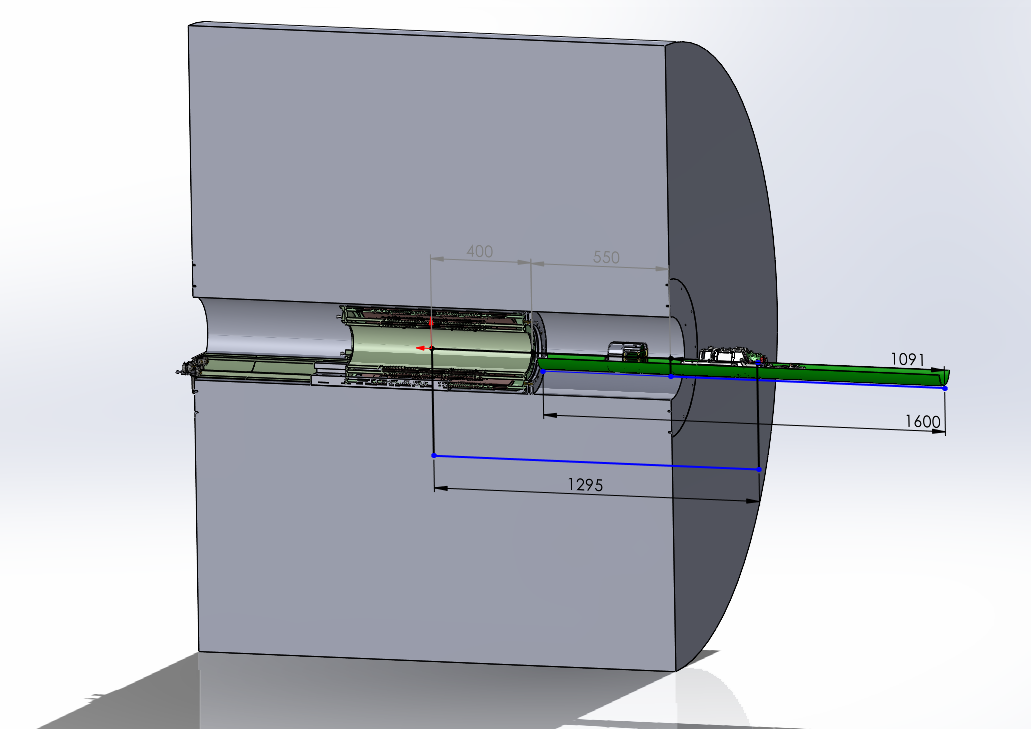

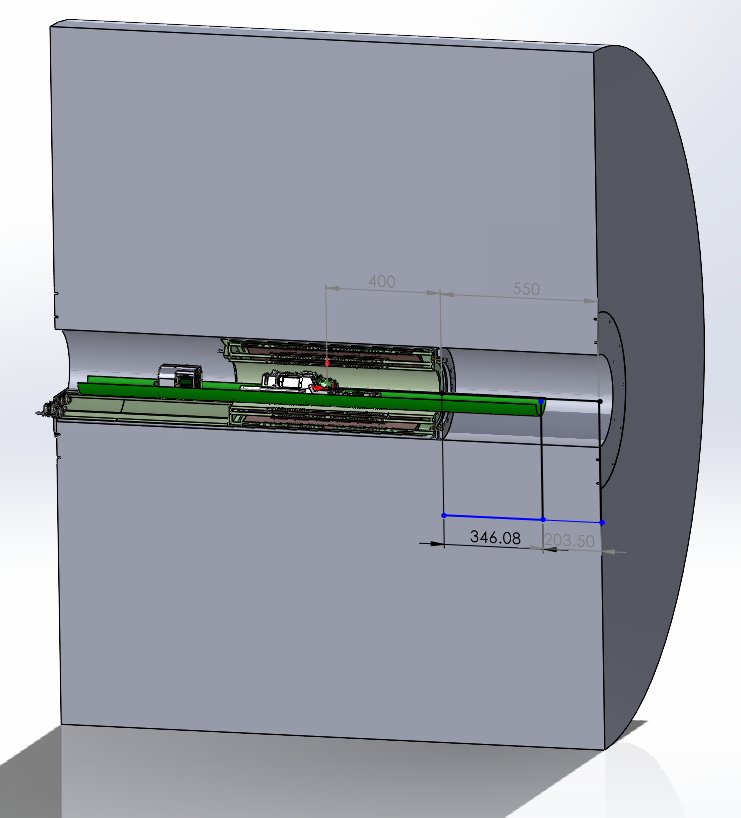

- No mechanism (track or ball screw) can be within the 550mm area so that it is not secured within the bore and is easily removeable on a cart.

- A overhanging platform will be needed that extends from the outside of the bore into the scanner while being attached to the bed.

- The tray needs to travel 1295mm to isocenter

Overhanging Platform Implementation

- I only have 314mm to secure the tray to the bed because I want an extra 30mm of travel past isocenter. Therefore the platform will be protruding 517.5mm into the bore at isocenter + any length for attachment to the bed outside. This length must be less than 409mm to keep the bed under 1.5m long.

Step 4: Actuation Type

Typical MRI bed actuation

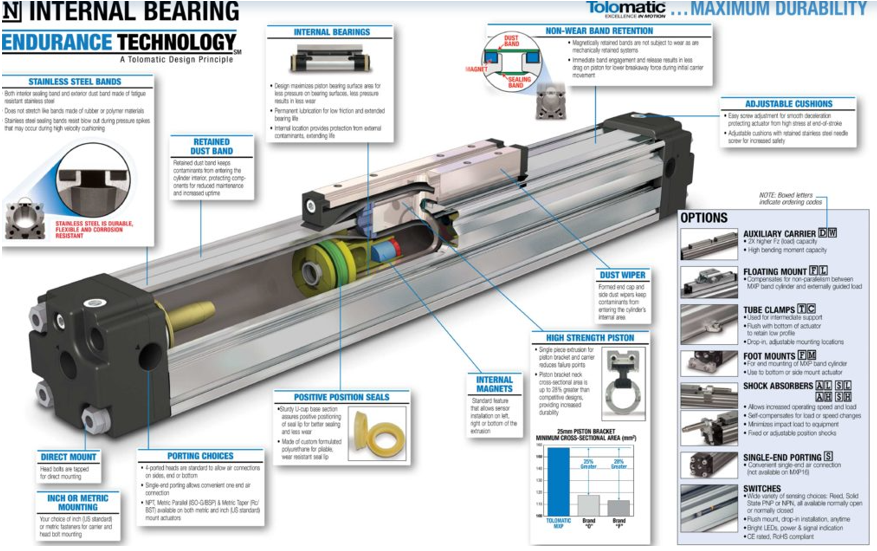

a. Pneumatic actuators, Rodless cylinders.

- Typical assemblies have magnetic parts. One option found where end covers would need to be changed. I’d have to reach out to other companies to further expand.

- Pros: large stroke length, no onboard electronics needed, large linear force.

- Cons: Requires compressed air source, and receiver tank. Immediate deal breaker.

Limited positional accuracy due to on/off valves have a switching dead zone, and friction causes overshoot.

b. Motors

- Pros: Straightforward implementation, use belt, lead screw

- Specialized motor needed for fully non-magnetic

- Needs enough torque

- Software needed

- Research found available piezoelectric motors for medical applications.

Drive Mechanism

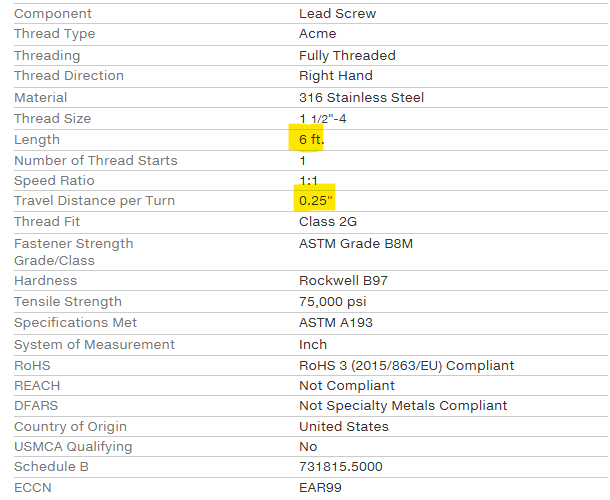

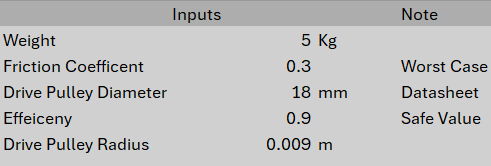

a. Lead Screw

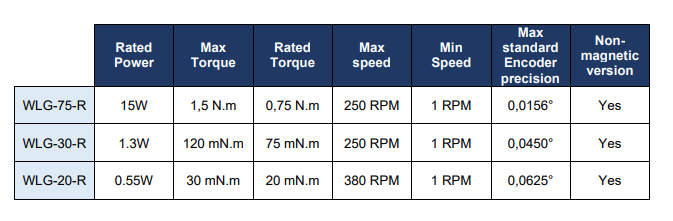

Available lead screw in this stroke length and non-magnetic material:

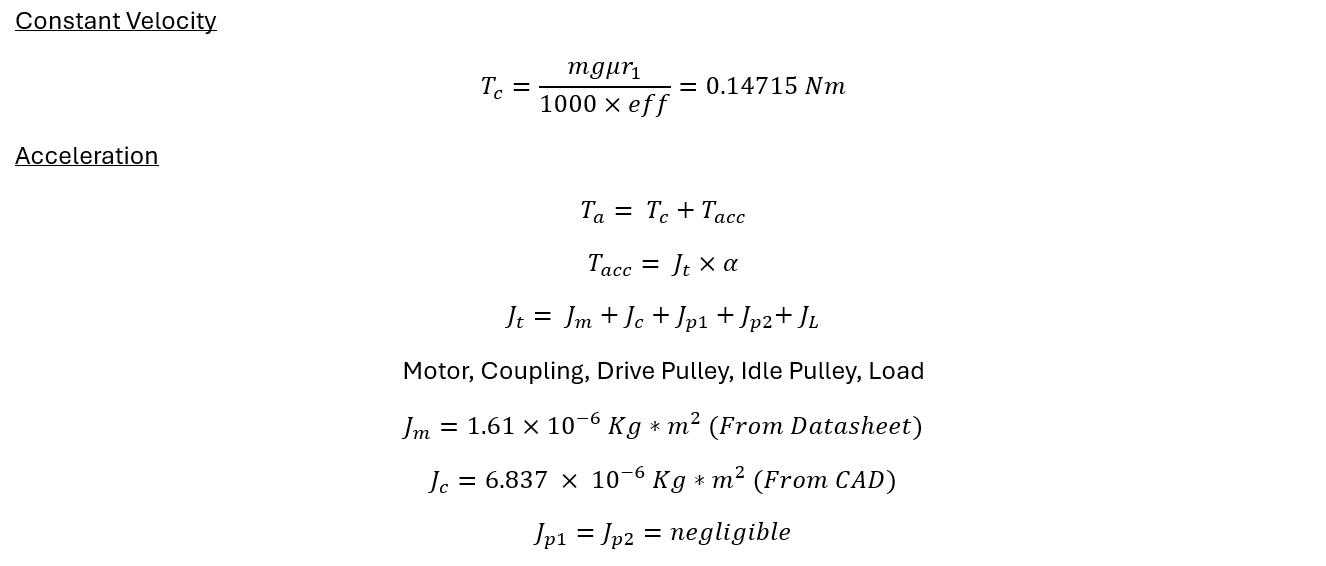

RPM = linear speed (mm/min) / lead (mm/rev)

=1384/6.35 = 218 RPM

Cons:

- Very expensive for just the lead screw (even without tariffs and tax)

- Motor needs operate at a high RPM which will be noisy and reduce lifetime

- Have to cut the lead screw to length

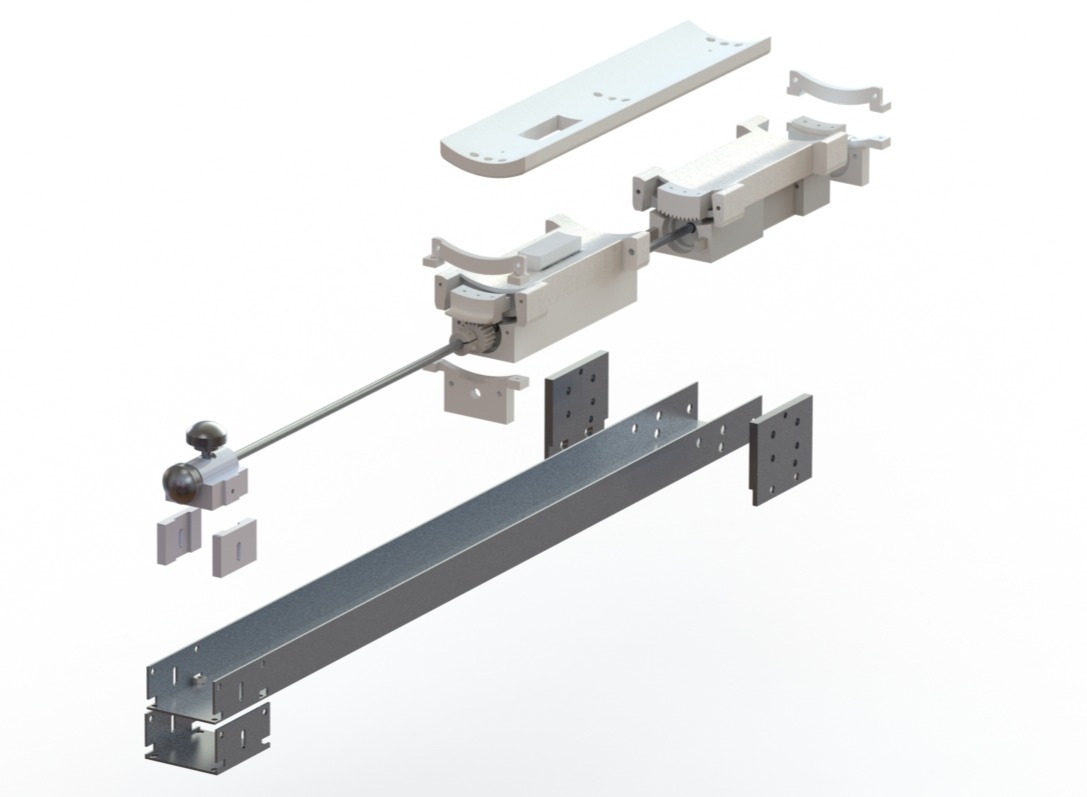

b. Belt Drive

Sourced custom non-magnetic belt drive for 1000 USD with 54mm/rev transmission.

RPM = 1384 mm/min / 54 mm/rev

= 25.6 RPM

Pros:

- All in one package, no extra cost

- No magnetic field interference

- Custom length, no modification

- Low motor speed, no noise and increase in motor life

Motor Torque

Mechanical Design

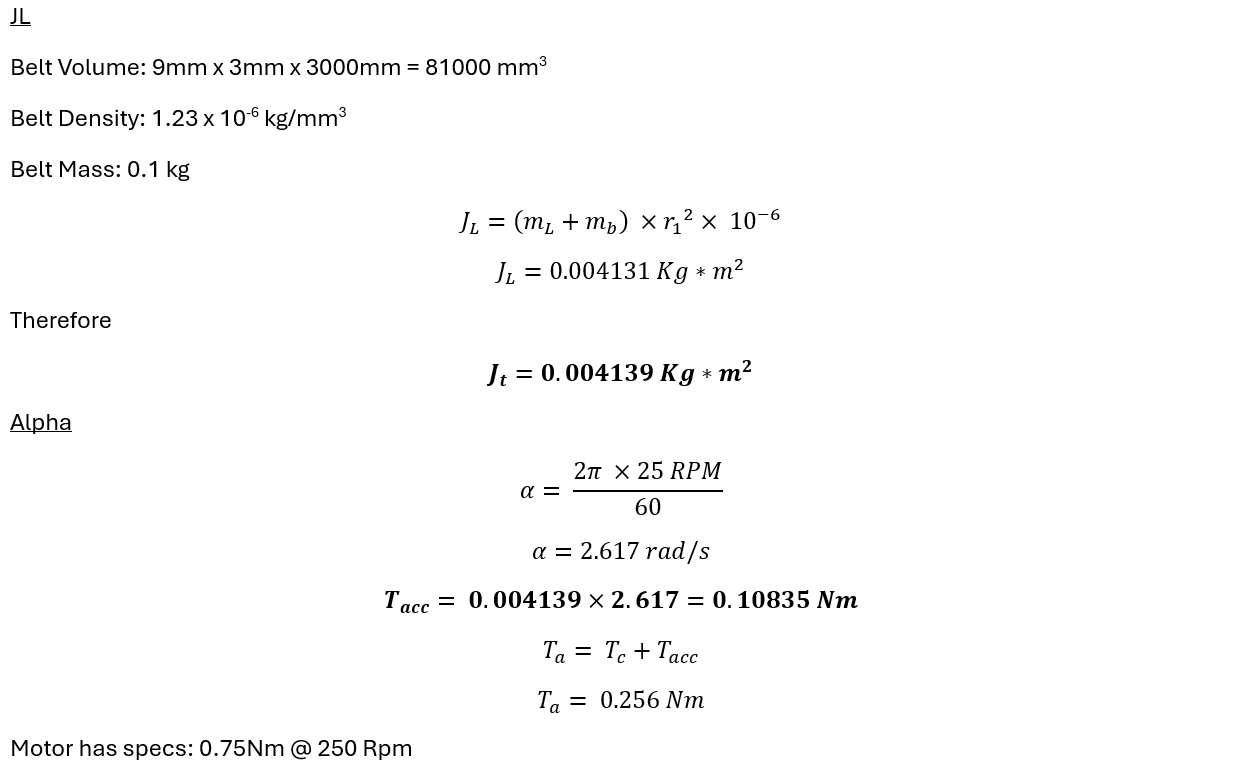

Frame and Drive Mechanism

- Originally Designed a removeable cart on wheels

- Needs of supervisor changed, and he now wanted a permanently installed version with no supports (cantilevered beam)

- With the frame already designed for the cart application, the weight of the modified version for the cantilevered beam was already determined.

FEA

Step 1: Simplified the Geometry for a static analysis

Step 2: Added the appropriate contacts/connections.

Step 3: Create the correct mesh

Step 4: Define the analysis settings.

Step 5: Material Properties

Step 6: Add the loads and fixed supports

Step 7: Analyzing the result files

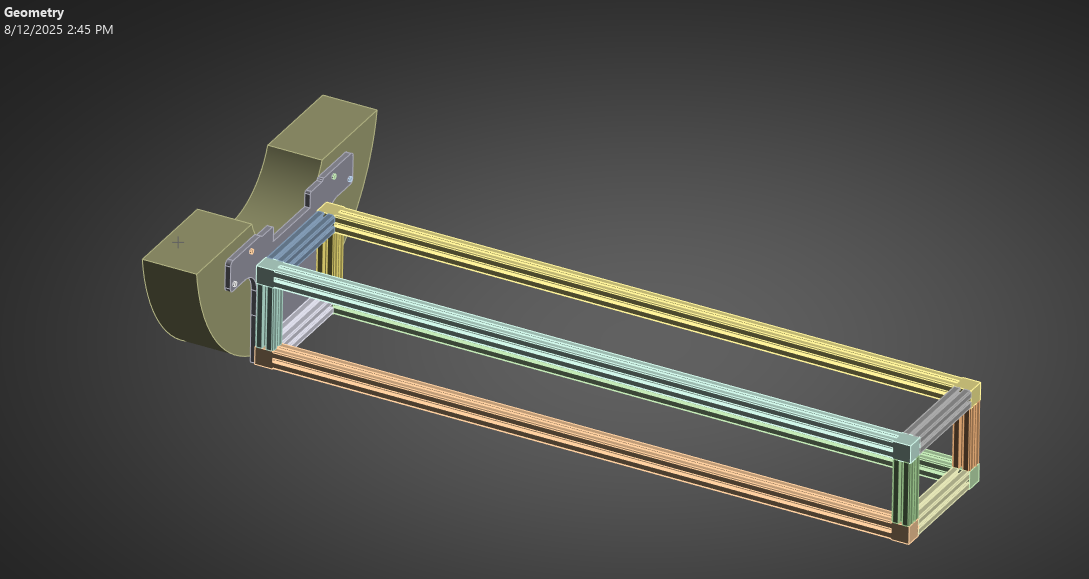

The goal here is to determine when bolt failure will occur and if the 4 M6 bolts will be sufficient for mounting without supports.

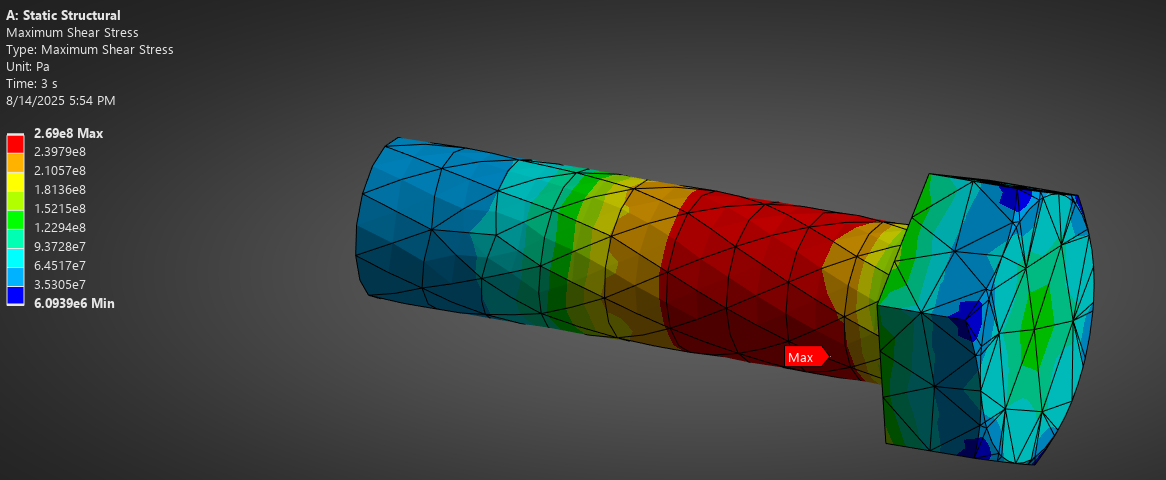

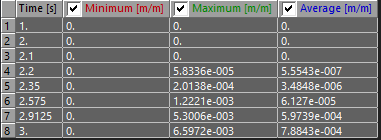

Equivalent Von Misses Stress in the highest stressed bolt

Tensile Yield Strength of the bolt is 450 MPA. We can see from the table that around 2.35 seconds the stress is 460 MPA. Therefore, at 2.3 seconds the load is 1900N (3000N/s x 0.3s = 900N). This indicates that if someone were to sit on the end of the frame, they would need to weigh 194 kg (427 pounds).

This is a large amount of weight, and it does give a large enough safety margin.

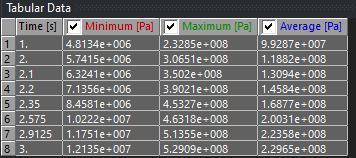

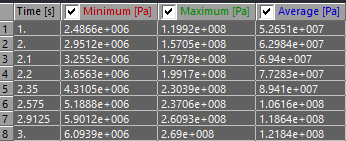

Maximum Shear Stress in bolt

Why is shear stress present after preload?

In ANSYS, Maximum Shear (Tresca) is a scalar derived from the principal stresses:

τmax=σ1−σ3/2

In simple uniaxial tension from a bolt preload, σ1=σaxial, σ1=σaxial, σ3 = 0.

τmax=σ1/2

At 2.3 seconds (1900 N) the maximum shear stress is 230 MPA. For this material, the shear yield is 260 MPa. THis would mean that the bolt would not fail, but as before the von misses combined bending, axial, and shear to identify yielding at 2.35 seconds.

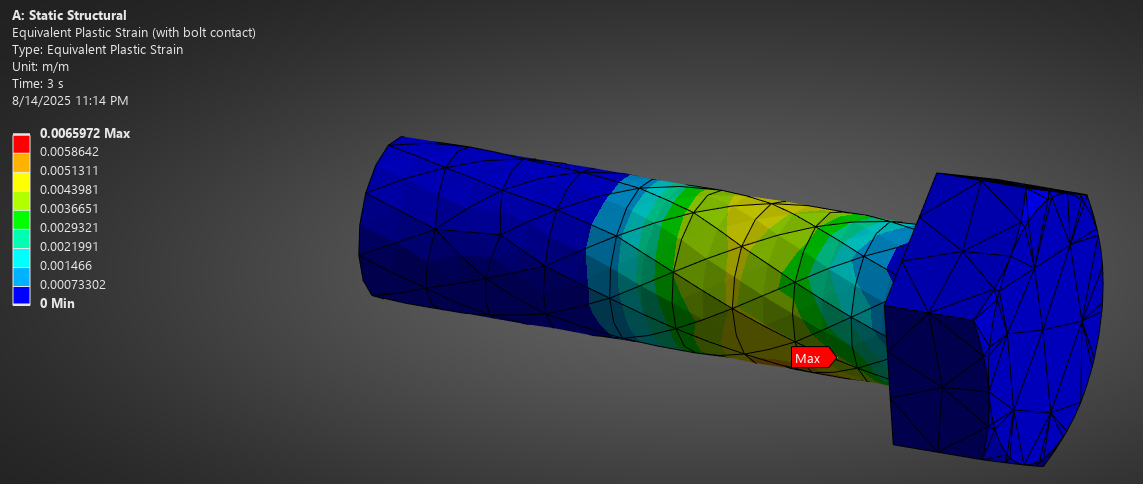

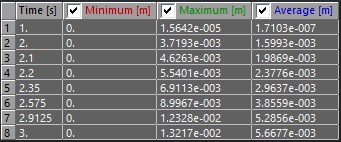

Equivalent Plastic Strain

We can actually look more in depth to see that plastic strain begins between 2.1 and 2.2 seconds, which will correspond to an external force of 1450 N. N(t) = 1000 + 3000(2.15 – 2).

This now equates to 147 Kg (324 lbs).

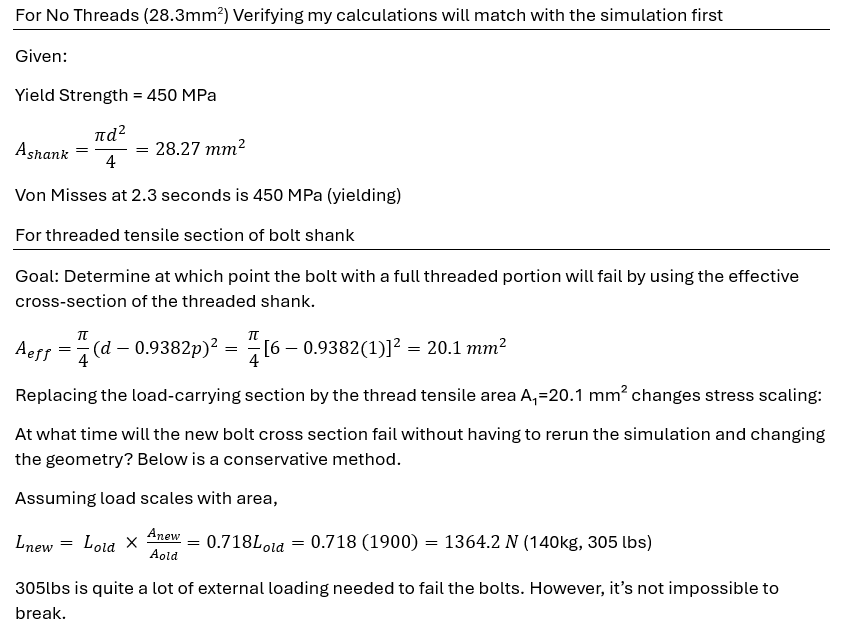

But we have to remember something. The modeled bolt is 6mm in diameter, and does not factor in the threads that create a thread tensile area of 20.1mm^2 instead of 28.3mm^2 cross section.

Lets do some calculations:

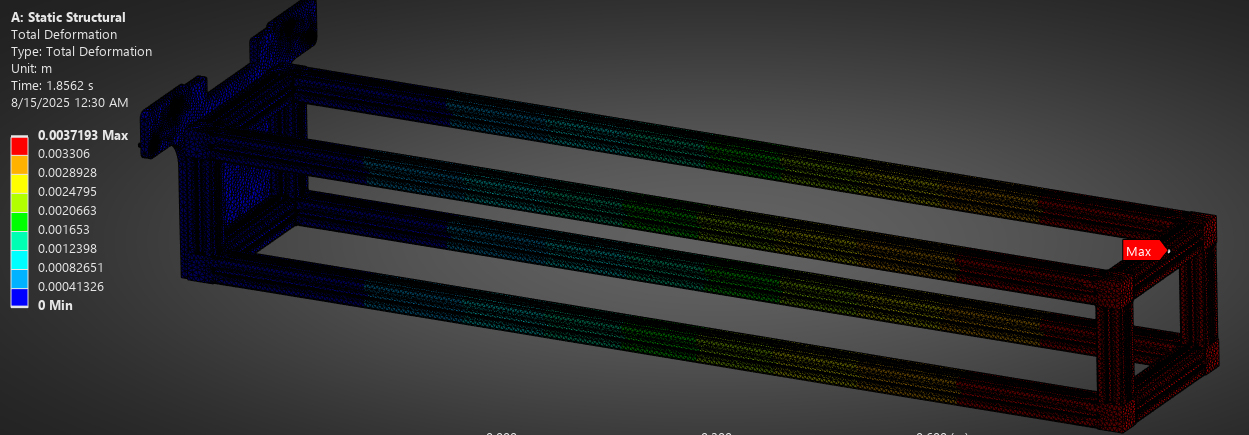

Deformation Results

We can see that with just gravity applied (Start of step 2) the end of the frame sags by 3.7mm. This is enough to cause misalignment in mechanical system and may cause problems that could have been avoided. Any small external load adds even more deformation.

In conclusion, it was decided that supporting legs at the end of the frame was the safe decision. The possibility of bolt yielding, and the sagging of the frame were something we didn’t want to try out and see what happens.

Also the effect of pushing on the frame and releasing is not known. It may cause the frame oscillate, further affecting the mechanism alignment and structural integrity.

Also, 316 stainless steel is very slightly magnetic. The magnetic field may loosen the bolts over time which is a big concern. If we selected brass bolts instead, these would fail almost instantly with a yield strength of only 265 MPa.

New Frame Design

Added support legs to the rear to eliminate the potential failure and deformation errors as discussed during FEA analysis.

Carriage Design

1. Aligns the tray into the bore.

2. Allows for vertical and rotational adjustment of the tray.

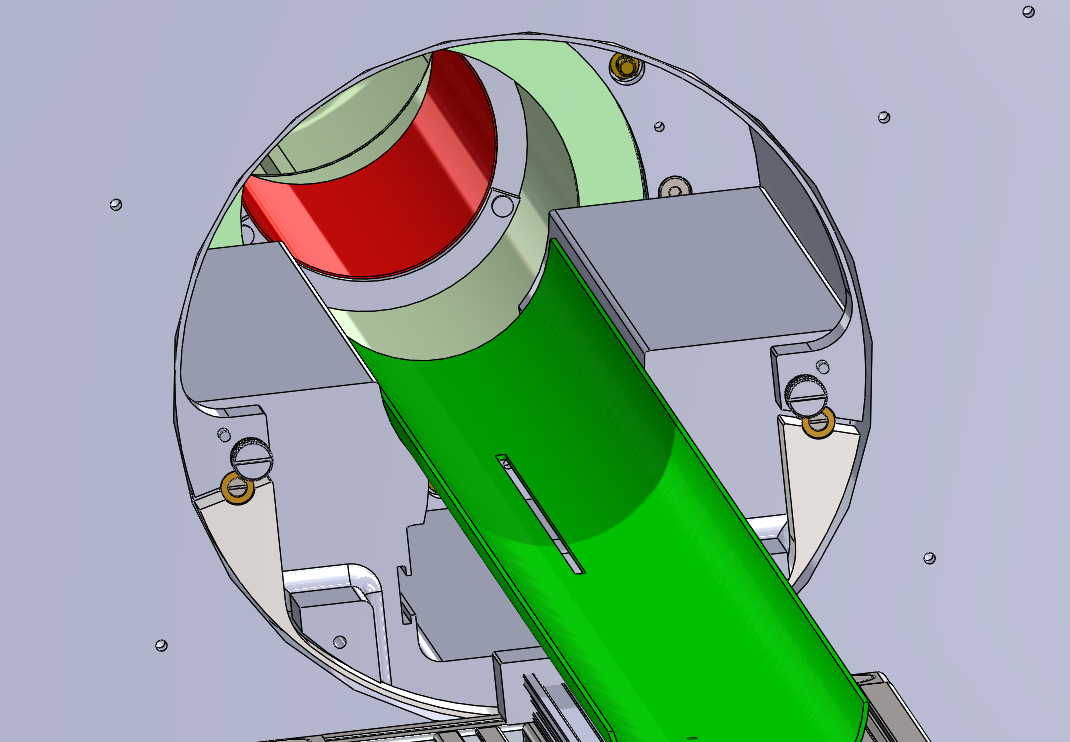

Bore Guide

Originally had the tray just be guided by the 3D printed bore guide due to the restriction of no permanent installation of parts in the bore.

However, this changed because this was now a permanent install instead of the removable cart design.

To ensure a full linear actuation, two linear guide rails were installed into the bore guide. It also ensured no sagging of the cantilevered beam.

Material of the guide rails were aluminum. No magnetic components.

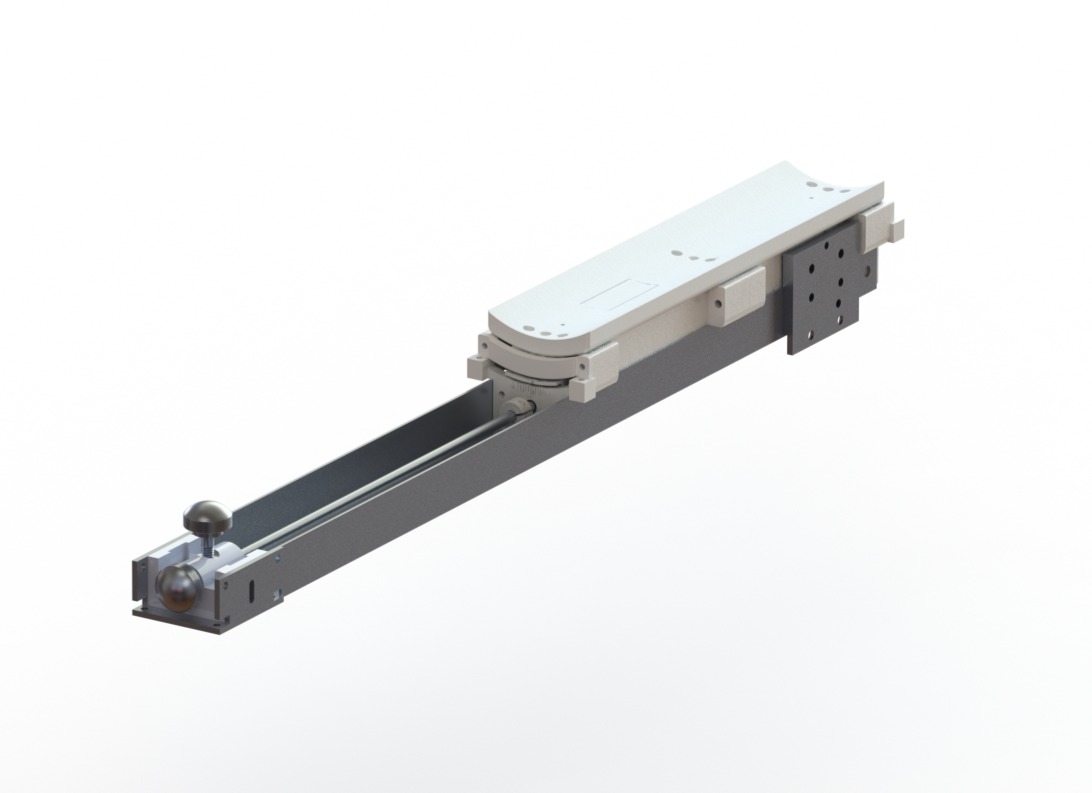

Finished Assembly

I also made a Cover for the bed, but my manager decided he liked the industrial look more.

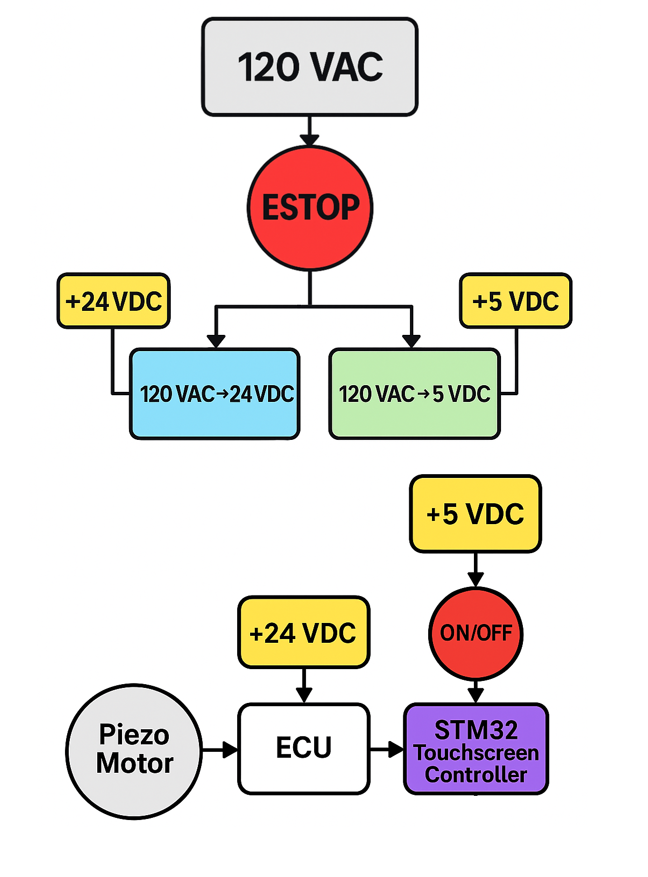

Electrical

Challenges

Results