How do Piezoelectric Motors Work?

Quick Explanation:

It’s a direct-drive motor with no magnets. You excite a piezo ring at ~40 kHz to make a tiny traveling ripple run around its toothed rim. Each tooth moves in a microscopic ellipse and, because a rotor is gently pressed on that rim, friction drags it around. If you flip the phase to reverse direction and nudge the frequency to set speed. An optical encoder closes the loop for precise positioning. The result is compact, quiet, MRI-safe, high-torque motion without a gearbox.

Big Picture

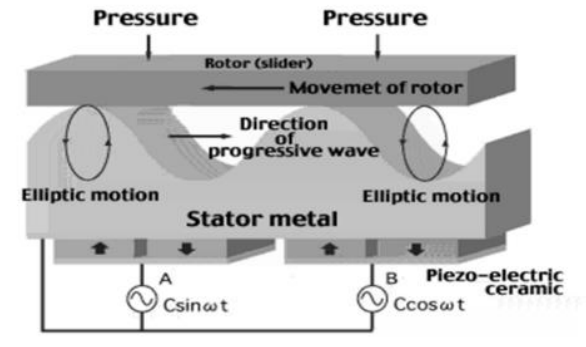

- a traveling-wave ultrasonic motor. Instead of coils & magnets, it uses a ring-shaped stator with bonded piezoelectric ceramics driven at ultrasonic frequency (~35–45 kHz) to create a traveling flexural wave along a toothed rim. Points on the stator rim move in tiny elliptical paths; a preloaded rotor rides on that surface and is dragged by friction.

How it Works

Stator is made of a piezoelectric material that generates vibrations when voltage is applied.

The material changes shape and deforms, and is able to return back to its original form in many cycles per second.

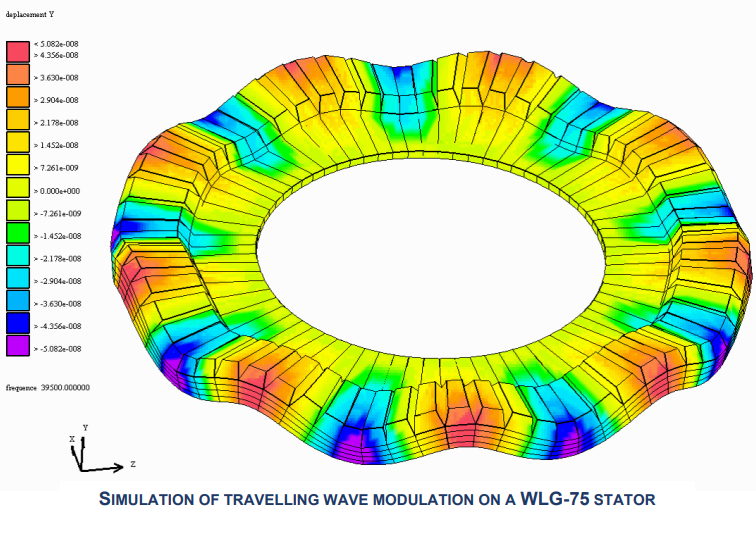

- Two bending modes of the stator at (nearly) the same natural frequency are excited with spatial and temporal 90° phase shifts (“sin/cos” drives on the piezo segments).

- Their superposition is a traveling wave circulating around the ring. Surface points trace ellipses at ultrasonic frequency. The ellipse’s tangential component drags the rotor.

Torque

- Torque arises from tangential friction between the rotor and the stator teeth, proportional to normal preload and the tangential velocity at the contact. Higher piezo drive voltage increases vibration amplitude and available torque (within thermal and wear limits)

- Because the rotor is preloaded, TWUSMs exhibit a high holding torque when unpowered (static friction brake). For the WLG-75-R the spec is 1.87 N·m holding torque.

Speed

In Tekceleo’s controller, speed is adjusted by frequency modulation around the stator’s resonance.