Jet Engines

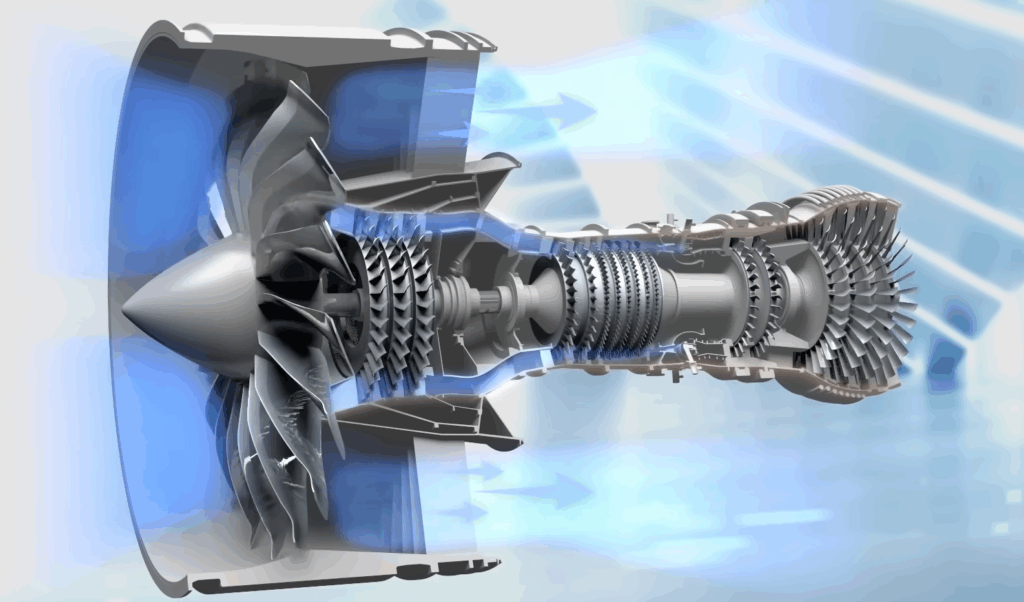

TurboFans

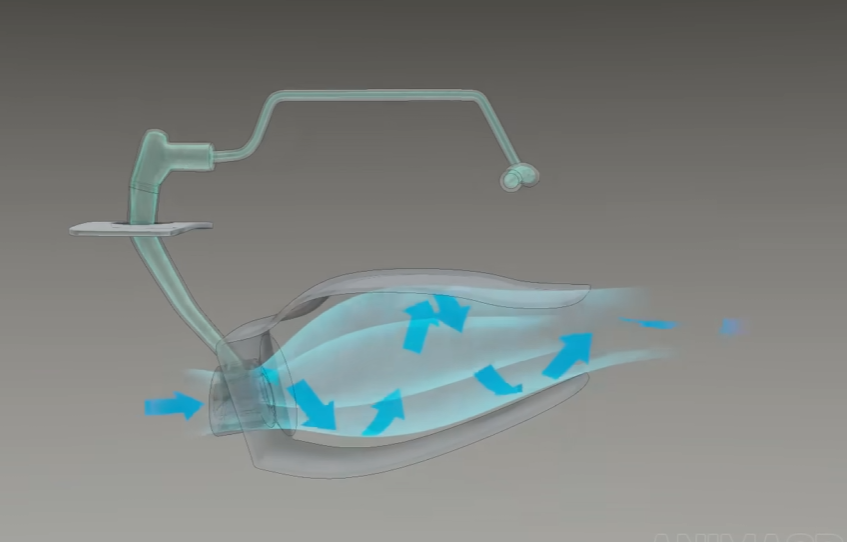

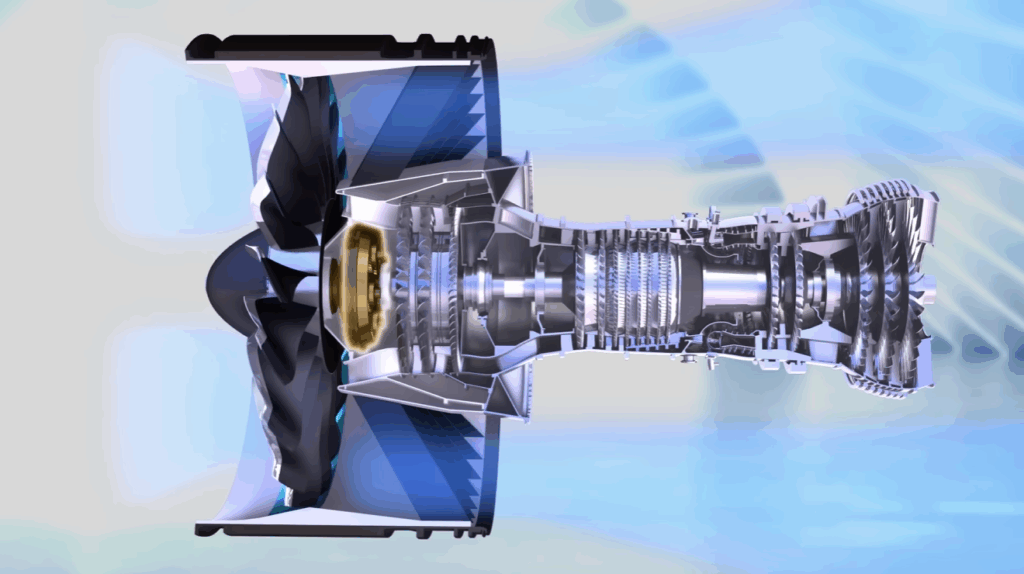

Turbofan pulls air around the engine inside the diffuser. Some of this air goes escapes to outside, and some air enters the core.

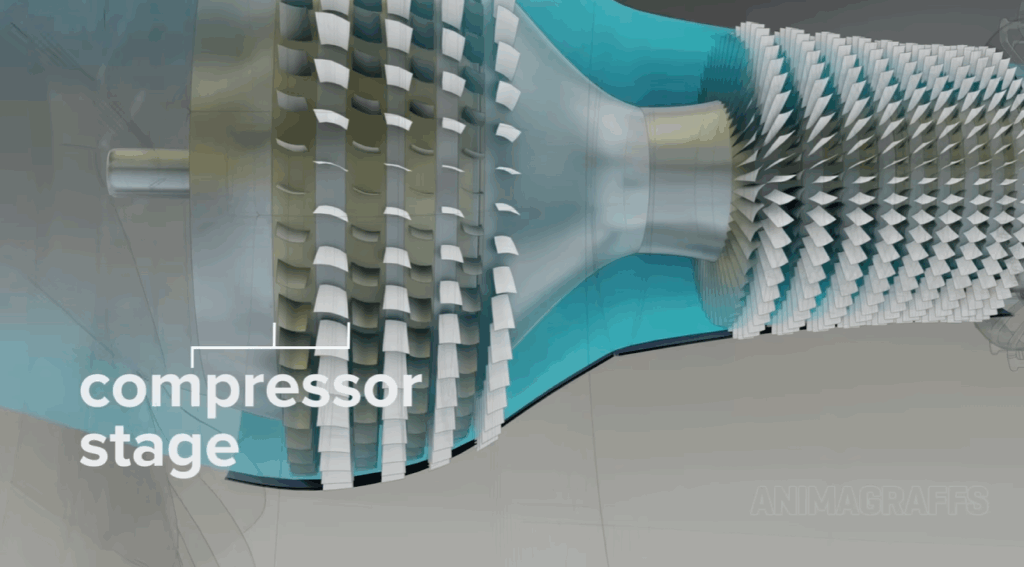

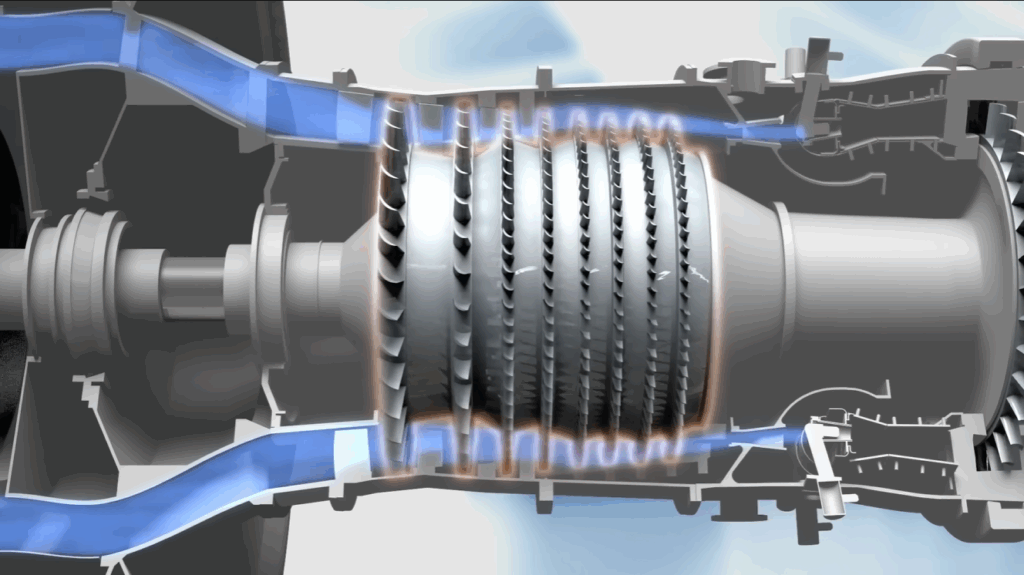

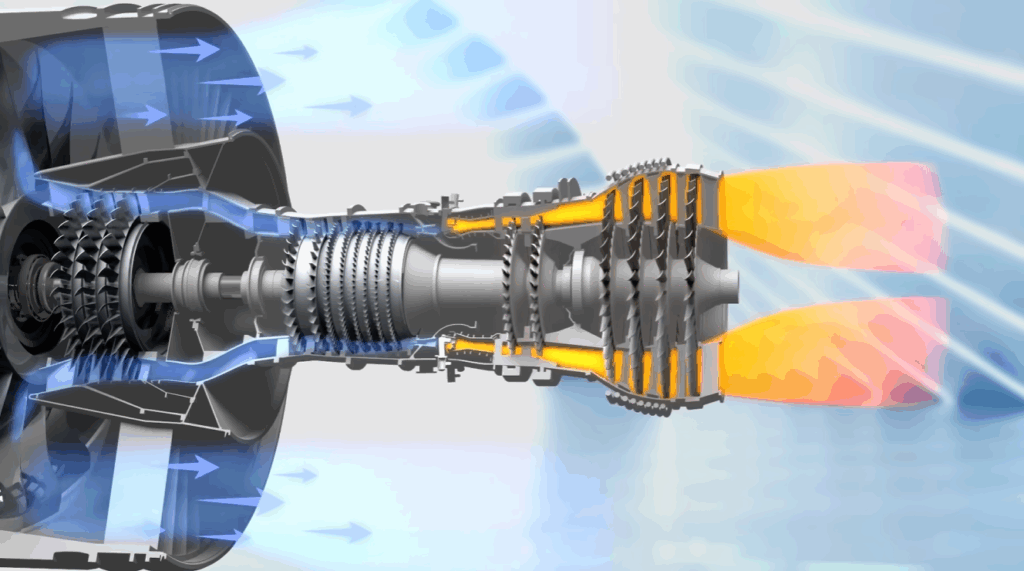

It goes into a compressor. Compressed air makes for a much more powerful combustion reaction. The first compression stages have 3-4 low pressure stage (on the left).

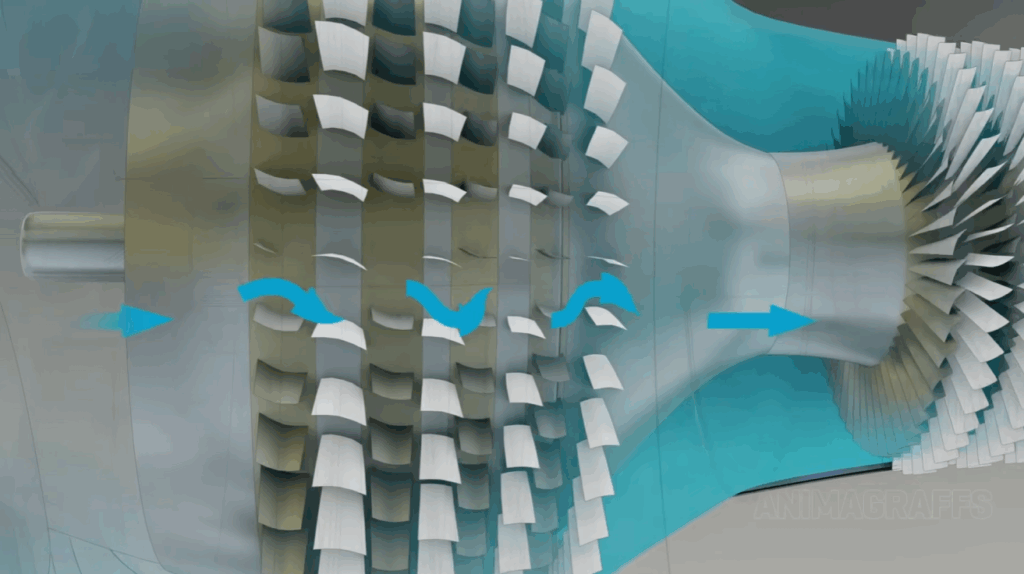

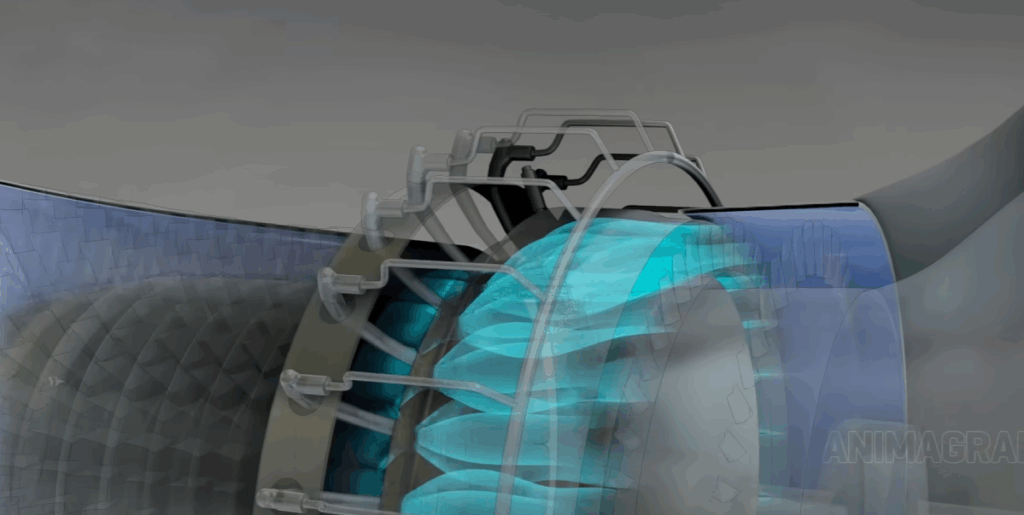

A compressor stage is comprised of a spinning rotor paired with a ring of stationary stator vanes which are attached to the core casing.

Rotor blades swirl the air as they force it through the compressor. Stator vanes slow this swirling momentum in exchange for increased air pressure.

Another compressor stage, where each fan gets smaller and smaller as the blades squeeze the air into a tighter and tighter space. This is the high pressure stages and have more stages than the low pressure stages.

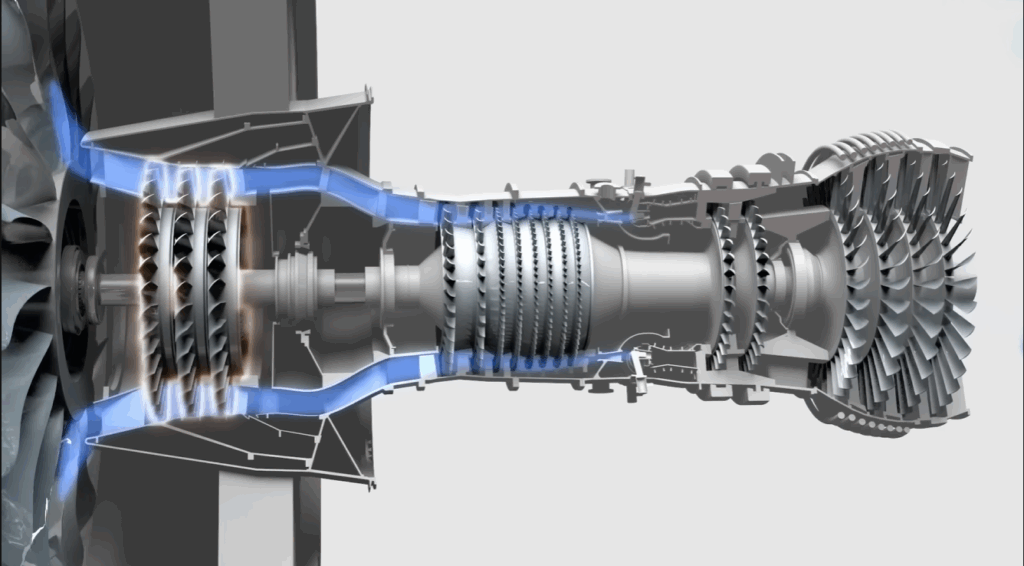

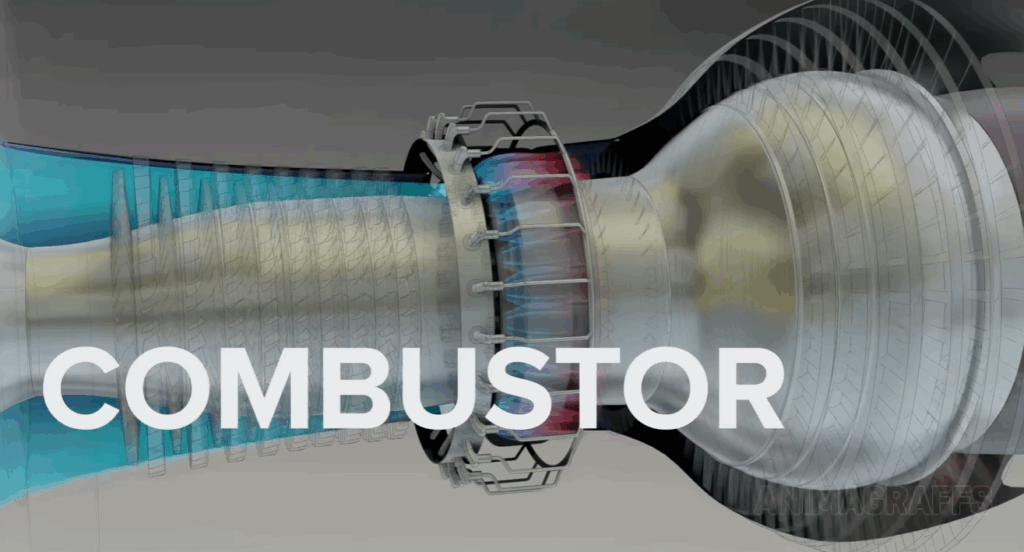

That squeezed air is mixed with jet fuel.

In the combustor, that air and fuel mixture meets a flame, and shoots out the back of the engine.

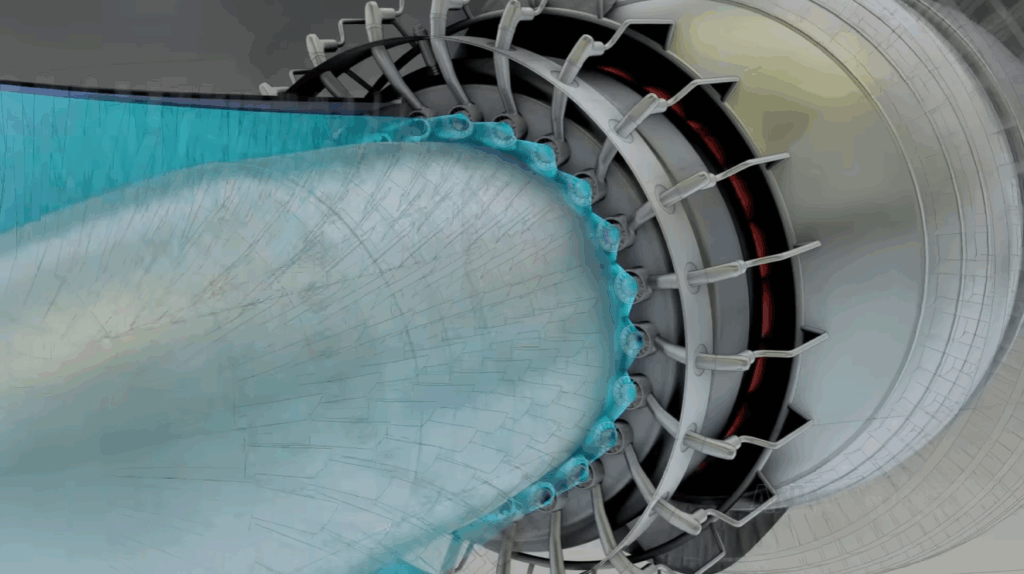

The design shown here is an annular combustor, meaning ring shaped.

Compressed air enters the inlet nozzles. Each nozzle is coupled with a fuel injector, and is designed to swirl the incoming fuel and air for an even mix.

A couple of ignitor plugs, ignite the mixture, and the reaction spreads evenly around the ring.

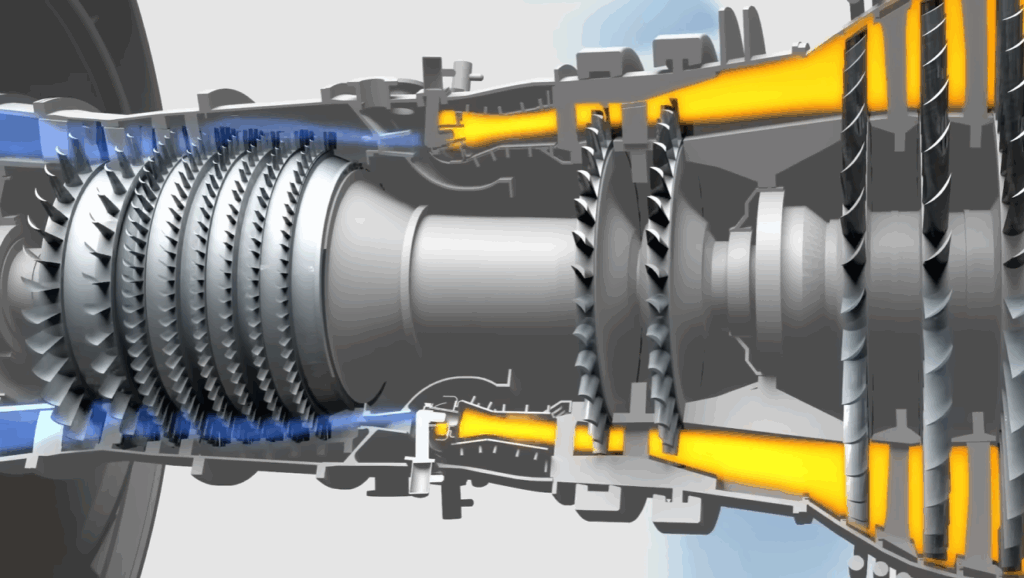

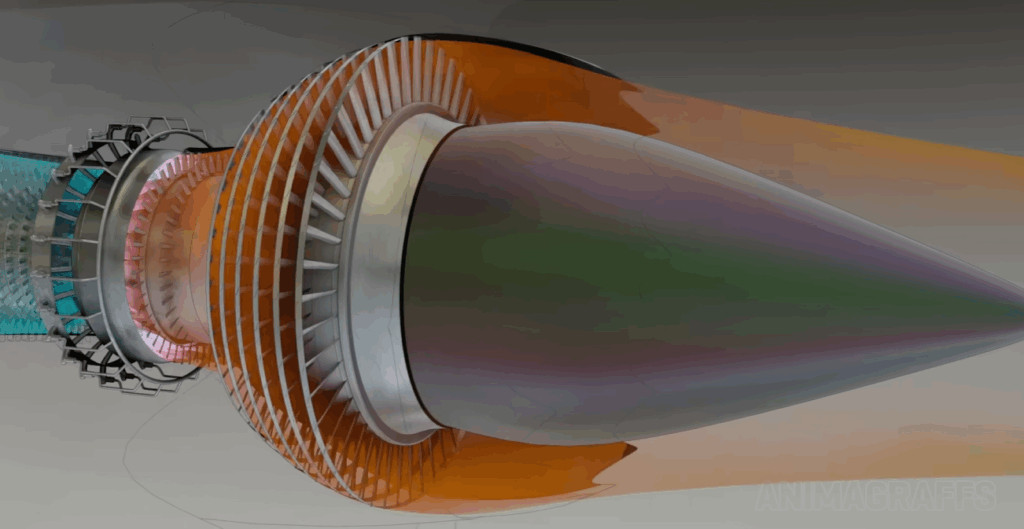

The rush of hot air (exhaust gasses) spins a turbine, which is like a windmill, that scoops up energy from the heated air. Much of the turbine power is used to turn the fan while a smaller percentage powers the compressor stages.

Turbine fins get extremely hot. Some air from the compressor is diverted for cooling, and special coating are used to keep temperatures down.

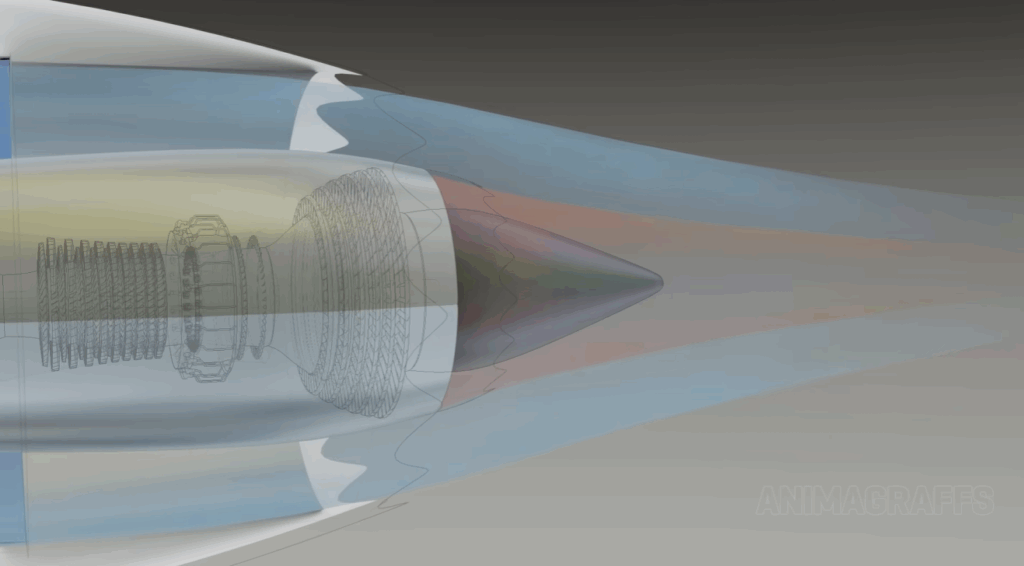

The excess hot air from the combustor, flows out the back of the engine, producing thrust.

High bypass air engines are designed to move large quantities of air at slower cruising speed.

Exhaust velocity is a major factor in jet engine noise. High bypass engines surround fast-moving core exhaust with large quantities of slower-moving air for quieter operation.

The air rushing outside the engine core, the turbine and fan push a larger mass of air than the core ever can, for much more thrust. That extra air passing around the engine core, works more efficiently if it moves more slowly than the hot air rushing out the combustor and the back of the engine.

Pratt designed an engine that lets the fan push air more slowly than the turbine, by putting an amazing gear between them. The pure power engine.

More in-depth

Fan Aerodynamics